You don’t have too look far on the internet these days to notice a lot of chatter about the marked rise in commodity prices. One particular market driving (quite literally) the increase is the demand for ‘battery materials’, the vital component in electric vehicles (EV’s).

It goes without saying that most of the first world is looking towards a greener future. Governments, businesses and individuals are waking up to the idea that unless we halt, or at least slow down our destruction of the environment, our future is looking somewhat bleak.

The carbon emissions in our atmosphere cause global warming so while big industry tackles their own emissions on a much larger scale, the average man or woman in the street can do their bit by swapping to an electric car – and they are warming to the idea in droves.

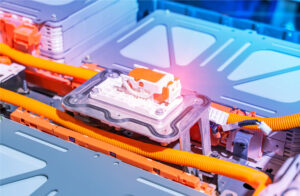

This surge in demand for EV’s is putting a strain on the stock levels of the raw materials required in the production of Lithium ion batteries and electric cars. This obviously has a knock on effect on prices.

Benchmark Mineral Intelligence confirms “The class of lithium ion battery and electric vehicle (EV) raw materials are all undergoing price rises as the industry braces for a demand jump in 2021.”

Simon Moores, Benchmark’s Managing Director, explains “For this suite of battery raw materials, China acts as an early warning system for the rest of the world. Historically, price rises that occur in China are usually experienced in the rest of the world 3 to 6 months later.”

The expected price increase is echoed by Goldman Sachs analysts in a report earlier this year.

“Prices for the three main natural resources have been rising since the start of 2021,” said the report “We believe that in order to promote sustainable EV industries, some countries may consider implementing policies to increase national stockpiles.”

The limited supply of some minerals could even cause a shift in the type of battery used by car manufacturers. A shortage of suitable nickel could potentially expedite the move to the alternative lithium ion phosphate (LFP) battery as used by Tesla and Xpeng. These batteries do not use nickel or cobalt but they do not store as much energy.

The increase in cost of raw materials inevitably leads to higher costs to the end user which is likely to have an adverse effect on consumer demand. The turning point for the public switch from fossil fuelled cars to electric will come about when the cost of battery production has fallen sufficiently for it to compete favourably. Despite the expected continuing price rise of the raw materials, Goldman predicts battery costs will fall below that of the internal combustion engine by 2030.

We make your life easier by managing your recruitment process for you, using our expertise and proven methods.

If we can help you to find the right candidate for your role, please get in touch with us today.